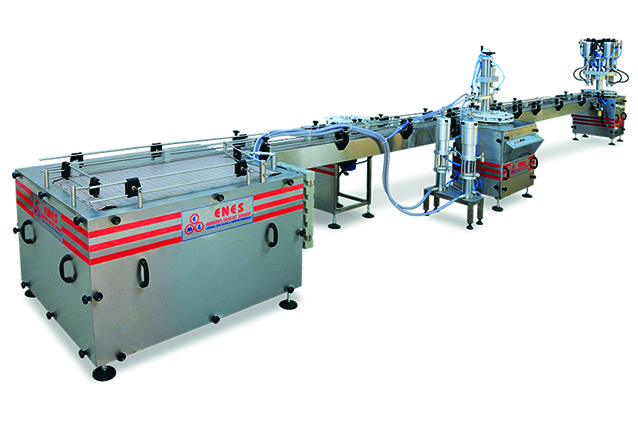

Some operations have been made manual with standart aerosol filling machine.

For Example : Valve Throwing, Actuator Stamping, Capping and Inkjet is made manually.

Firstly, empty cans have been carried to liquid filling by the convoyeur. Valves is put by hands and then cans pass from valve crimping and then goes to gas filling. After the gas filling, cans are crimping manually thereafter cans are closed by hands and after the opsional inkjet unit, products is ready to packing.

|

TECHNICAL PROPERTIES |

|

|

Gas Pressure |

8 bar |

|

Air Pressure |

8-10 bar |

|

Product Capasity |

50-60 cans(of 200 ml) |

|

Max. Gas Filling Capasity |

400 gr |

|

Air Consumption |

3500 lt/min |

|

Total Length |

13 m |

|

Electrical Parameters |

220 V – 3 kW |

Keywords : aerosol filling machine, aerosol filling and crimping machine, spray filling machine, aerosol dolum makinası, aerosol dolum ve kapatma makinası, sprey dolum makinası, filling machine, dolum makinası, gas filling machine, gaz dolum makinası, liquid filling machine, likit dolum makinası, aerosol cans, aerosol kutusu, aerosol cans filling machine, aerosol kutu dolum makinası, full automatic aerosol filling machine, semi-automatic aerosol filling machine, manual aerosol filling machine, tam otomatik aerosol dolum makinası, yarı otomatik aerosol dolum makinası, manuel aerosol dolum makinası